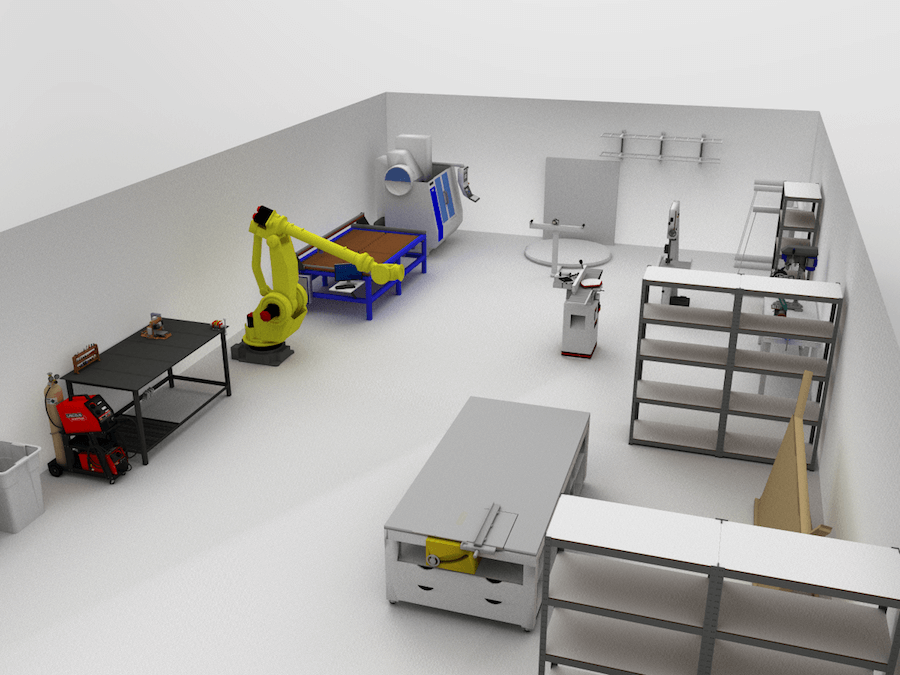

Turning the Workshop into an Industrial Fabrication Shop

In late March of this year, I found myself looking for a small project that would land me far away from any kind of electronic screen. That ominous glow of the monitor bleaching the joy out of my soul during the Winter months had taken a toll. Cleaning up the workshop seemed like a good fit.

What started as some light sweeping and reorganization, soon became back of the napkin blueprints heavily designed around simple HF&E (Human Factors and Ergonomics) principles. Shelving units needed to be reinforced, tools needed to be categorically separated, and then subdivided by the most probable task groups.

Before long, it was another temporal obsession.

The spontaneous projects that were started, in progress, or are completed as a result:

3-Axis Router

A 3-axis router designed around a standard Dewalt 1.75 HP Router.

A 15 RPM 4 Foot Diameter 3D Scanner

This was a last minute design as a result of an autonomous lawnmower project. I needed a way to easily scann larger objects, in order to design components for the actuator to ‘grab’ the brake, gas, etc.

A 3-in-1 Mobile Saw Table

I designed and built this around a Craftsman table saw, a jig saw, and a router. I have yet to design the sled and fence to maximize the table’s utility.

Injection Mold Machine

It seemed silly to build a 3-axis router, making molds a breeze in the process, without adding in a small injection molding machine. Its essentiall just an extrusion element with a heating component to melt PLA, etc.

Electric Melting Furnace

This item was added purely for the enjoyment of solving the challenges of the build. I’ve wanted to set aside the time to learn a bit of metallurgy for years, and this will expedite the process.

Details to follow